| Density (kg/m3) | 64-128 |

| Thickness (mm) | 10-120 |

| Length (m) | 1-6 |

| Width (m) | 0.6 |

| Maximum working temperature | 1260-1430-1600 |

| Thermal conductivity in 24 (w/m.k) | 0.036 |

| Packaging | carton |

Ceramic Fiber Insulation:

Ceramic Fiber is produced from high purity alumina and silica material through strictly controlled high temperature furnace melting and fiberizing process. The fiber is white and odorless, suitable for high temperature applications up to 1630°C and used for insulating tank, barrel, arc and electrical furnaces.

Ceramic Fiber Blanket:

Ceramic fiber blanket, is a type of insulation refractory material, featuring high strength, light weight, non-asbestos and organic binder, good high temperature stability and good insulation performance.

This kind is manufactured in 64,96,120 densities and recommended to use in heat exchange, tank, different furnaces and all sizes and thickness will be supplied according to customer’s order.

Due to its advantages, it is widely used in many fields such as lining for high-temperature reaction equipment and heating equipment in chemical industry, lining for industrial furnaces, high temperature filter material and fire protection and thermal insulation materials of high buildings.

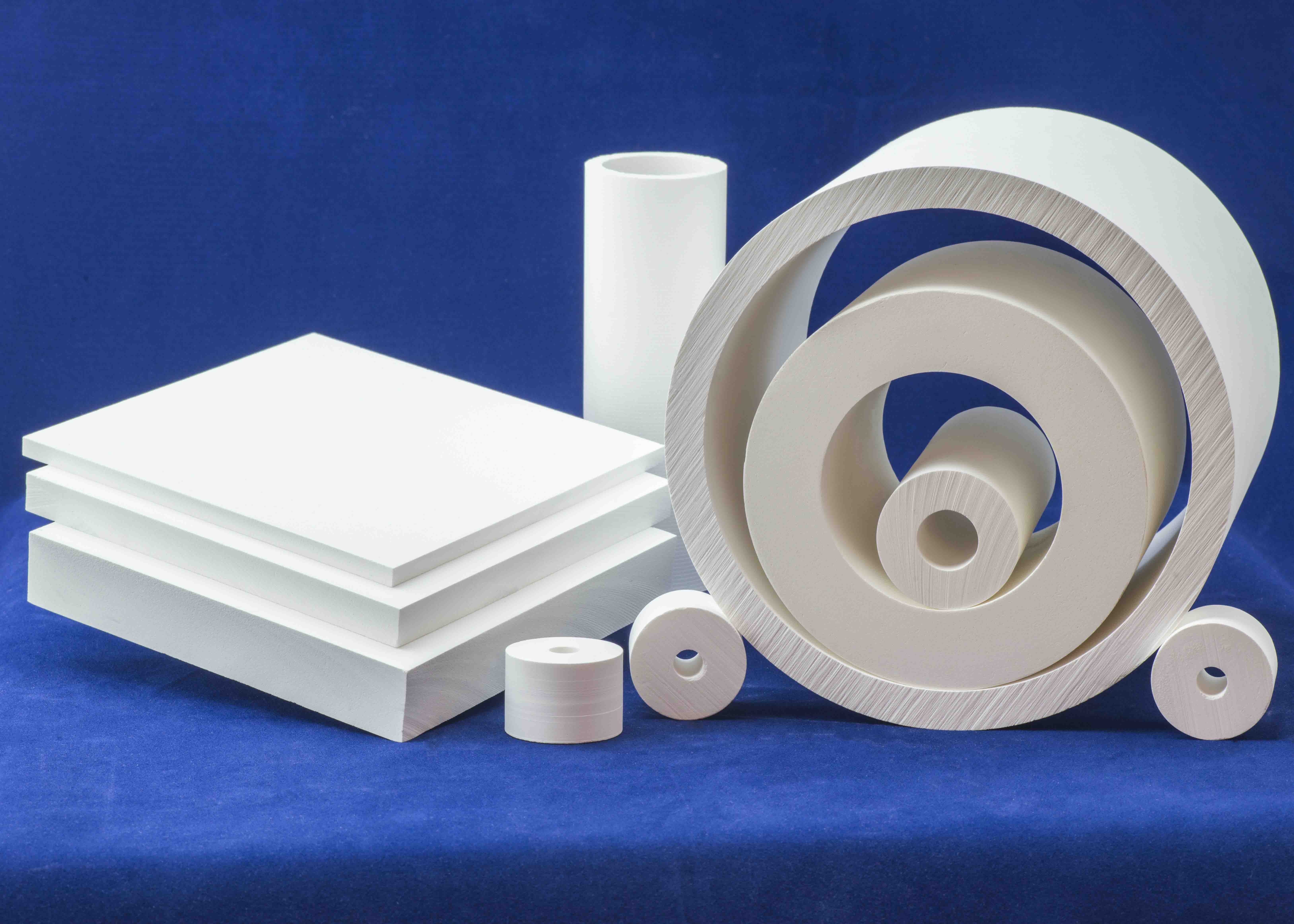

Ceramic Fiber Board:

Refractory ceramic fibre board is a vacuum formed product that resists higher gas velocities than ceramic fibre blanket. Ceramic fiber board is ideal for furnace, boiler duct and stack lining due to its low thermal conductivity and low heat storage allowing shorter cycle times and quicker access for maintenance.

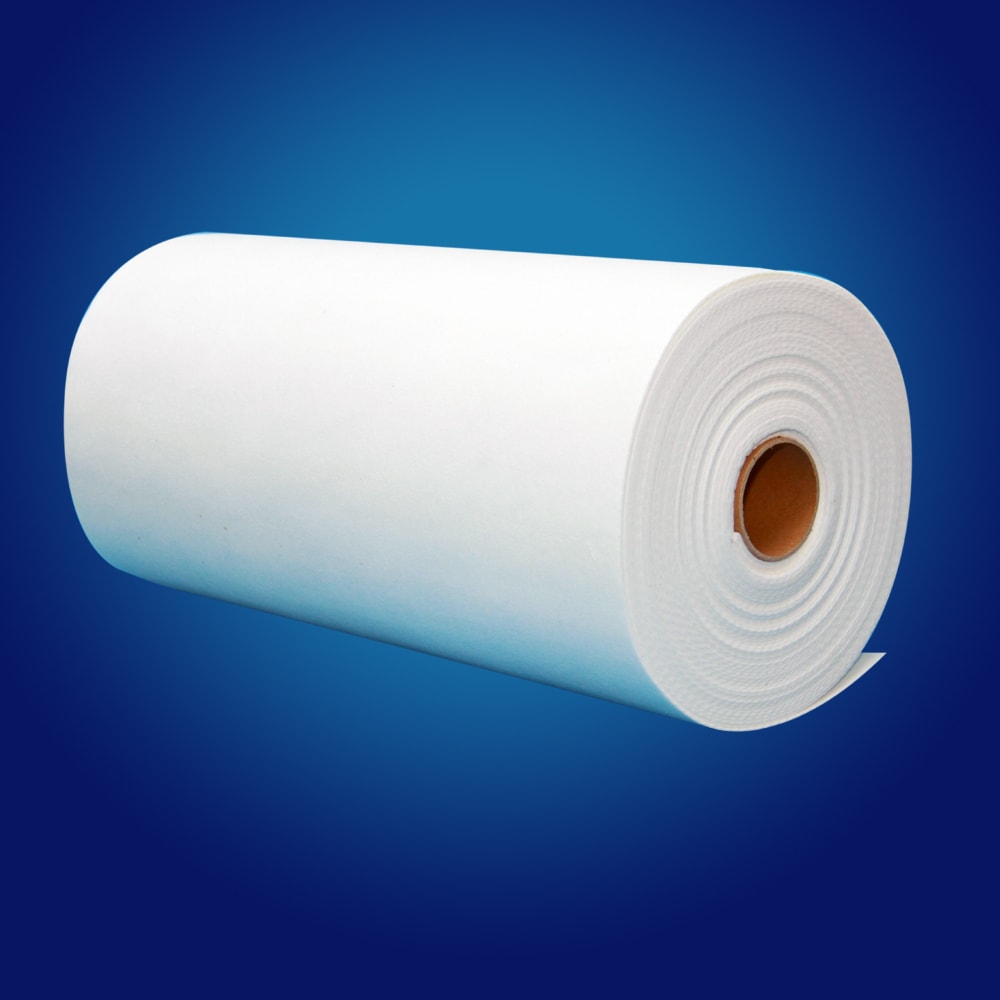

Ceramic Fiber Paper:

ceramic fiber paper features lightweight, structure uniformity and low thermal conductivity which can be supplied in all sizes and densities belongs to customer’s order.

Typical Applications:

-

- Insulation, lining and gasket for furnace, kiln, oven, stove, boiler and appliance;

- Wrapping for high temperature pipe or metal casting;

- Aerospace insulation, protection and shields;

- Thermal insulation, gasket, seal, separator for ceramic and glass melting applications

Ceramic Fiber Paper is used to solve a wide variety of heat-related problems. These papers exhibit excellent chemical stability, resisting attack from most corrosive agents. Our product finds application in various industries like Steel and metallurgy, Petro-chemistry, Automotive, Aerospace, Appliance, and many others.

Technical Specification

- Standard Sizes

- Thickness: 1/32″, 1/16”, 1/8”, 1/4″

- Width: 24″ and 48″

Ceramic Fiber Yarn:

Ceramic Fiber Yarn is manufactured from high quality spun fiber 1260°C or 1430°C, and has been mechanically twisted to give it tensile strength

Applications

Sewing thread for high temperature textiles

High temperature gasket

Production of textiles

Ceramic Fiber Rope:

Twisted rope is fabricated from ceramic fiber yarn twisted left hand/right hand together to form a rope of specified diameters ranging, with glass filament, stainless steel wire or high temperature alloy wire inserted to provide high strength at elevated temperature.

Ceramic Fiber Vacuum Forming:

vacuum formed components are designed to meet specific application requirements in a wide range of industries

Application:

- Consumable shapes used in metal casting

- Combustion chambers for boilers, furnaces, and stoves

- High temperature burner blocks

- Low mass Kiln furniture

- Low mass kiln car tops

Ceramic Fiber Module:

Ceramic Fiber Modules are designed to deliver maximum energy saving and insulating benefits with low heat storage. Ceramic fiber Modules can be used in various furnace and heating applications. The most common uses include annealing, tempering furnaces, combustion chambers, oxidizers, burn-off ovens, kilns, incinerators, fired heaters, ducts and more

Ceramic Fiber Bulk:

This kind is produced with Ceramic Fiber Blanket and can be used in high-temperature condition.

FOR MORE INFORMATION CONTACT US.

FOR MORE INFORMATION CONTACT US.

- PRODUCT GALLARY

-

- DESCRIPTION

-

Ceramic Fiber Insulation:

Ceramic Fiber is produced from high purity alumina and silica material through strictly controlled high temperature furnace melting and fiberizing process. The fiber is white and odorless, suitable for high temperature applications up to 1630°C and used for insulating tank, barrel, arc and electrical furnaces.

Ceramic Fiber Blanket:

Ceramic fiber blanket, is a type of insulation refractory material, featuring high strength, light weight, non-asbestos and organic binder, good high temperature stability and good insulation performance.

This kind is manufactured in 64,96,120 densities and recommended to use in heat exchange, tank, different furnaces and all sizes and thickness will be supplied according to customer’s order.

Due to its advantages, it is widely used in many fields such as lining for high-temperature reaction equipment and heating equipment in chemical industry, lining for industrial furnaces, high temperature filter material and fire protection and thermal insulation materials of high buildings.

Ceramic Fiber Board:

Refractory ceramic fibre board is a vacuum formed product that resists higher gas velocities than ceramic fibre blanket. Ceramic fiber board is ideal for furnace, boiler duct and stack lining due to its low thermal conductivity and low heat storage allowing shorter cycle times and quicker access for maintenance.

Ceramic Fiber Paper:

ceramic fiber paper features lightweight, structure uniformity and low thermal conductivity which can be supplied in all sizes and densities belongs to customer’s order.

Typical Applications:

-

- Insulation, lining and gasket for furnace, kiln, oven, stove, boiler and appliance;

- Wrapping for high temperature pipe or metal casting;

- Aerospace insulation, protection and shields;

- Thermal insulation, gasket, seal, separator for ceramic and glass melting applications

Ceramic Fiber Paper is used to solve a wide variety of heat-related problems. These papers exhibit excellent chemical stability, resisting attack from most corrosive agents. Our product finds application in various industries like Steel and metallurgy, Petro-chemistry, Automotive, Aerospace, Appliance, and many others.

Technical Specification

- Standard Sizes

- Thickness: 1/32″, 1/16”, 1/8”, 1/4″

- Width: 24″ and 48″

Ceramic Fiber Yarn:

Ceramic Fiber Yarn is manufactured from high quality spun fiber 1260°C or 1430°C, and has been mechanically twisted to give it tensile strength

Applications

Sewing thread for high temperature textiles

High temperature gasket

Production of textiles

Ceramic Fiber Rope:

Twisted rope is fabricated from ceramic fiber yarn twisted left hand/right hand together to form a rope of specified diameters ranging, with glass filament, stainless steel wire or high temperature alloy wire inserted to provide high strength at elevated temperature.

Ceramic Fiber Vacuum Forming:

vacuum formed components are designed to meet specific application requirements in a wide range of industries

Application:

- Consumable shapes used in metal casting

- Combustion chambers for boilers, furnaces, and stoves

- High temperature burner blocks

- Low mass Kiln furniture

- Low mass kiln car tops

Ceramic Fiber Module:

Ceramic Fiber Modules are designed to deliver maximum energy saving and insulating benefits with low heat storage. Ceramic fiber Modules can be used in various furnace and heating applications. The most common uses include annealing, tempering furnaces, combustion chambers, oxidizers, burn-off ovens, kilns, incinerators, fired heaters, ducts and more

Ceramic Fiber Bulk:

This kind is produced with Ceramic Fiber Blanket and can be used in high-temperature condition.

-

- THICKNESS

-

FOR MORE INFORMATION CONTACT US.

- INSTALLATION

-

FOR MORE INFORMATION CONTACT US.

English

English