| 64-250 | DENSITY (kg/m3) |

| 25-150 | THICKNESS(mm) |

| – | LENGTH(m) |

| – | WIDTH(m) |

| 1600 | MAXIMUM TEMPERATURE |

| 0.045 | THERMAL CONDUCTIVITY IN 24 (w/m.k) |

| SHIRINK |

PACKAGING |

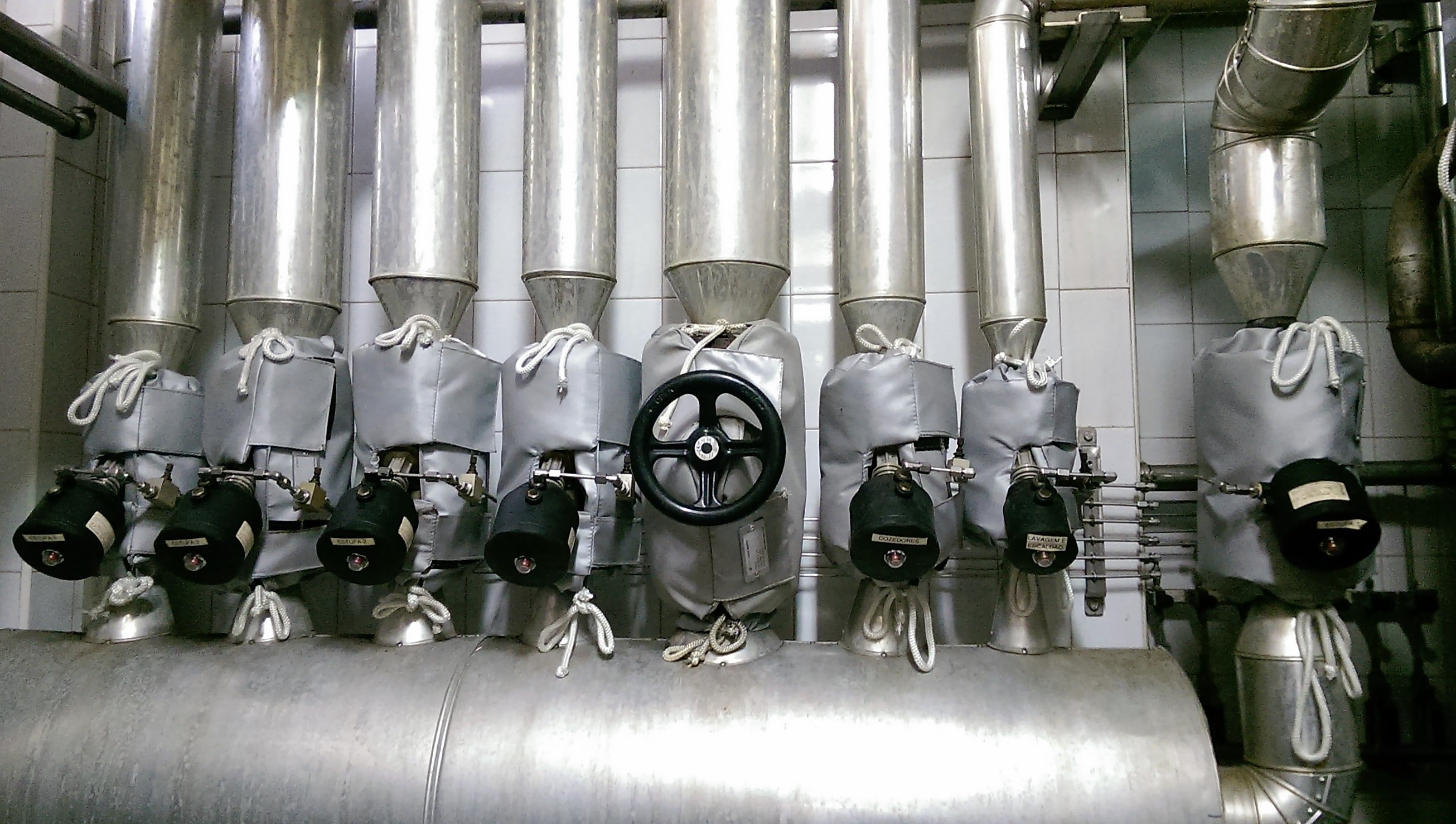

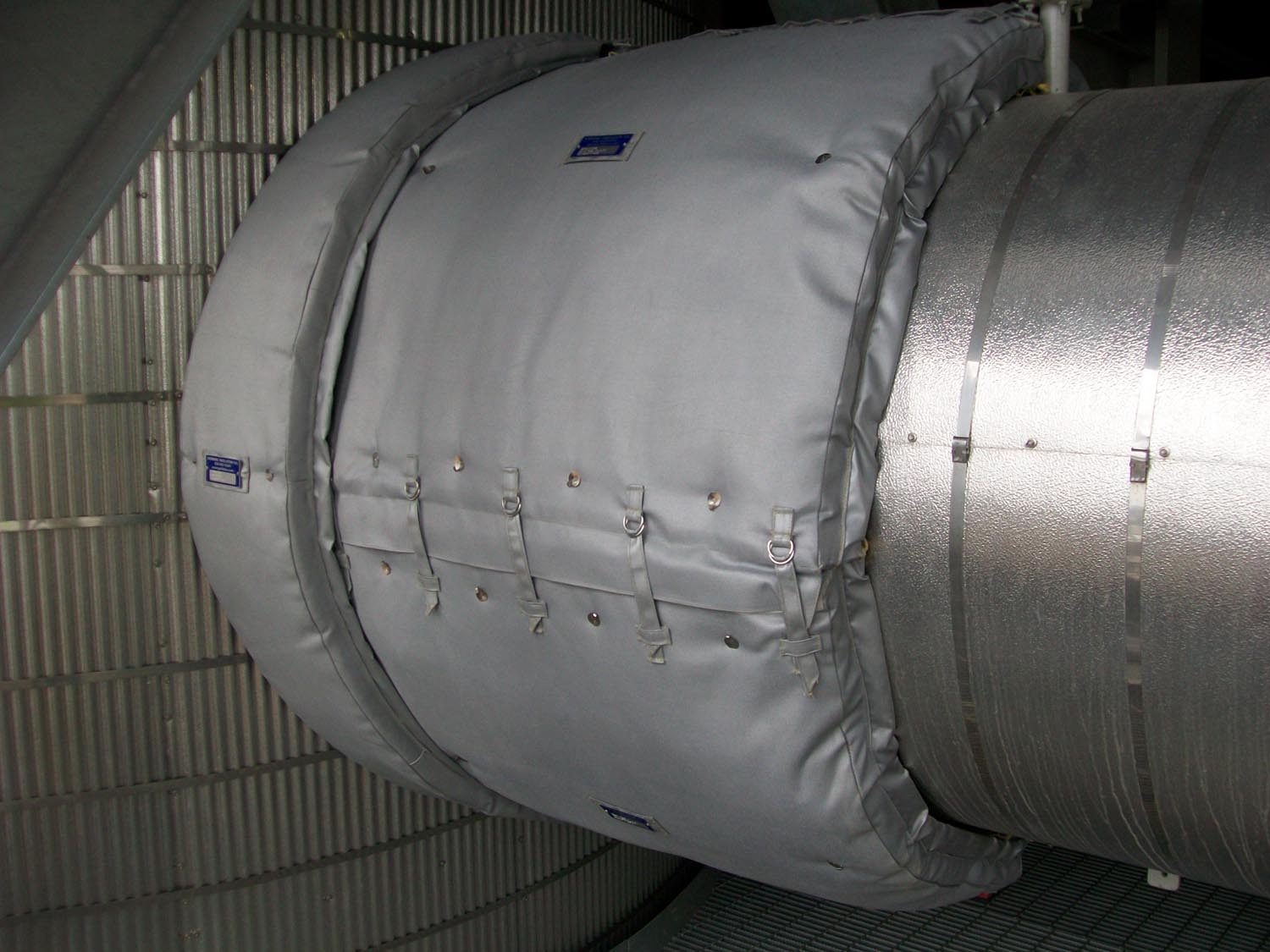

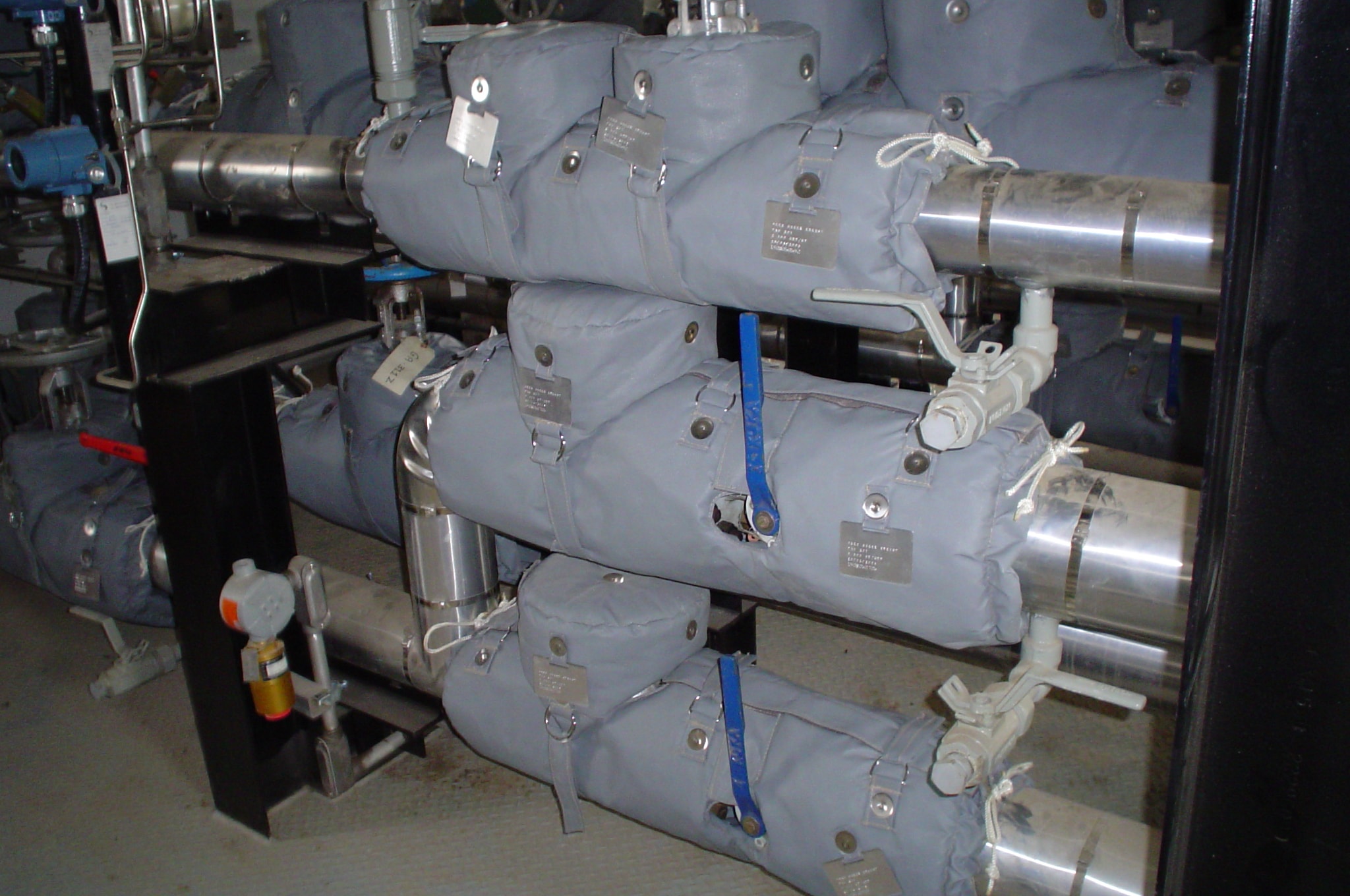

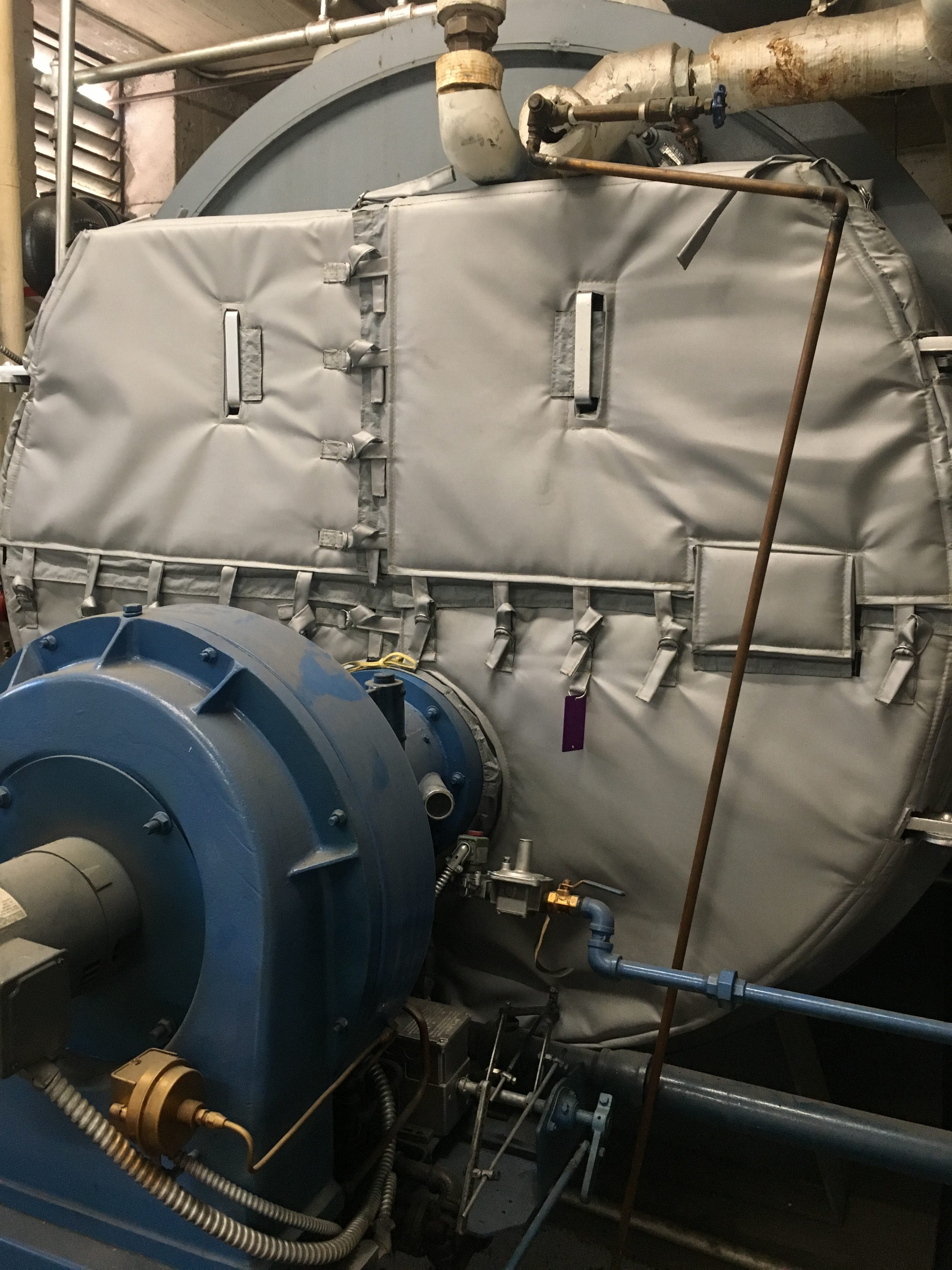

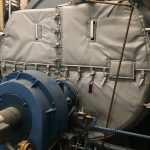

THERMAL INSULATION JACKET

The thermal insulation jacket/blanket/cover is used especially on industrial applications, e.g. plastic (extrusion, injection, blow moulding) industries, construction, etc. It can be customized according to customer requirement, e.g. the design of the applied products. It is very flexible to use and easy to install.

The insulation jacket offers a cost efficient solution which can save energy consumption to 30%. And it can lower the temperature of the products which can prevent operators from burning or scalding.

The removable thermal insulation jackets (covers) can be fabricated in many different ways depending on the materials used, the application and the customer requirements. Usually, The removable thermal insulation jacket consists of surface layer, insulation layer, and liner and/or anti-abrasion layer inside. Seams are sewn with high temperature threads, usually with Kevlar TM, PTFE coated glass fiber or stainless steel thread to suit application.

The service temperature depend upon the different materials used, the highest temperature is 1600(C).

ADVANTAGE

- Save 20%-45% energy in general

- The surface temperature can be lowered to 40degree centigrade , and thus safe to touch by hands

- Made to order by customer’s requirement to ensure 100% fit between heaters and jackets

- Easy to install by buckles, by aligning the wiring terminals and thermocouple holes

- Improve the quality of plastic products due to stable temperature

- Short return on investment period (with 20% energy saving rate, it takes 4 to 5 months to recover the cost. The higher the rate is, the less time it takes)

- Long usage life of jacket (also can extend the life of heater by preventing it from continuous heating. And thus extend the lives of barrel and screw)

- Water and oil proof, multi layer protection, anti corrosion, easy to clean, easy to bend, pollution free and neat out looking.

l Dimension, cut/hole sizes and positions are required for quotation. Drawings and pictures are preferred.

Applications:

1.Barrels of injection, extrusion, blow moulding and filming machine

2.Steam turbines, gas turbines (as turbine blankets) and compressors

3.Exhaust systems of engines, Generators

4.Heat exchangers

5.Pumps, Valves & Flanges

6.Expansion Joints, Flex Hose

7.Tank Covers

FOR MORE INFORMATION CONTACT US.

FOR MORE INFORMATION CONTACT US.

- PRODUCT GALLARY

-

- DESCRIPTION

-

THERMAL INSULATION JACKET

The thermal insulation jacket/blanket/cover is used especially on industrial applications, e.g. plastic (extrusion, injection, blow moulding) industries, construction, etc. It can be customized according to customer requirement, e.g. the design of the applied products. It is very flexible to use and easy to install.

The insulation jacket offers a cost efficient solution which can save energy consumption to 30%. And it can lower the temperature of the products which can prevent operators from burning or scalding.

The removable thermal insulation jackets (covers) can be fabricated in many different ways depending on the materials used, the application and the customer requirements. Usually, The removable thermal insulation jacket consists of surface layer, insulation layer, and liner and/or anti-abrasion layer inside. Seams are sewn with high temperature threads, usually with Kevlar TM, PTFE coated glass fiber or stainless steel thread to suit application.

The service temperature depend upon the different materials used, the highest temperature is 1600(C).

ADVANTAGE

- Save 20%-45% energy in general

- The surface temperature can be lowered to 40degree centigrade , and thus safe to touch by hands

- Made to order by customer’s requirement to ensure 100% fit between heaters and jackets

- Easy to install by buckles, by aligning the wiring terminals and thermocouple holes

- Improve the quality of plastic products due to stable temperature

- Short return on investment period (with 20% energy saving rate, it takes 4 to 5 months to recover the cost. The higher the rate is, the less time it takes)

- Long usage life of jacket (also can extend the life of heater by preventing it from continuous heating. And thus extend the lives of barrel and screw)

- Water and oil proof, multi layer protection, anti corrosion, easy to clean, easy to bend, pollution free and neat out looking.

l Dimension, cut/hole sizes and positions are required for quotation. Drawings and pictures are preferred.

Applications:

1.Barrels of injection, extrusion, blow moulding and filming machine

2.Steam turbines, gas turbines (as turbine blankets) and compressors

3.Exhaust systems of engines, Generators

4.Heat exchangers

5.Pumps, Valves & Flanges

6.Expansion Joints, Flex Hose

7.Tank Covers

- THICKNESS

-

FOR MORE INFORMATION CONTACT US.

- INSTALLATION

-

FOR MORE INFORMATION CONTACT US.

English

English